So, you’re thinking about upgrading your warehouse and making your storage smarter? Great move! An automatic storage retrieval system can change how your warehouse operates. But here’s the thing: deciding between a vertical carousel and a vertical lift module (VLM) can be a bit like choosing between pizza toppings—you want the one that’s just right for your needs. So, let’s break down the differences and help you make the best decision!

What is an Automatic Storage Retrieval System?

First things first—what exactly is an automatic storage retrieval system? It’s a fancy way to describe machines that help you store and retrieve items quickly and automatically. Think of them as the hardworking robots in your warehouse. They save you time, maximize space, and reduce the chances of errors. They’re like your own team of superheroes that help you manage inventory with ease!

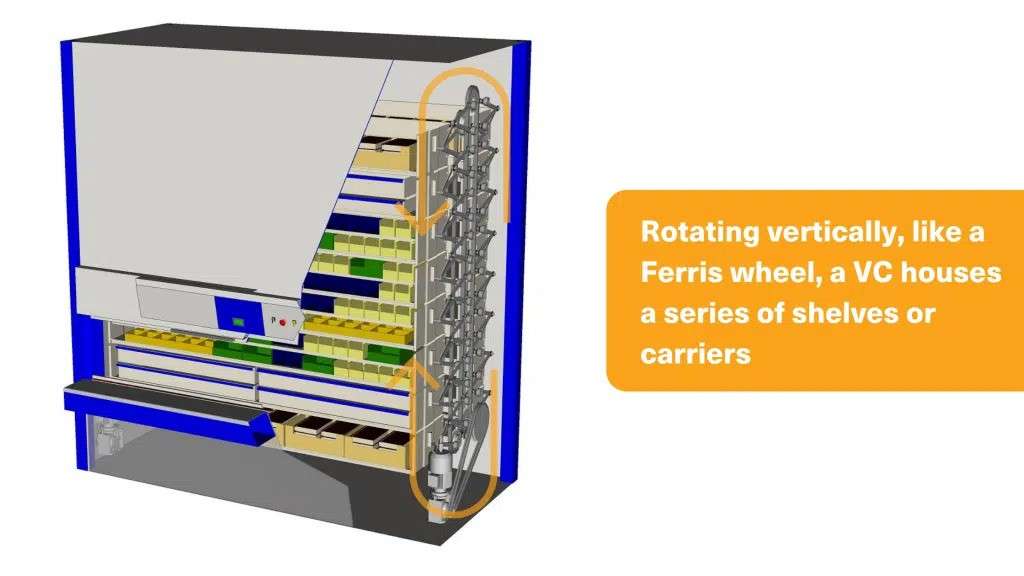

The Basics of Vertical Carousels

Now, let’s talk about vertical carousels. Imagine a giant Ferris wheel, but instead of people, it’s carrying trays of items. The trays rotate around a central axis, bringing the desired tray right to you. No more wandering through aisles and climbing shelves! Vertical carousels are designed to hold similarly-sized items, making them great for high-density storage. They’re best when you need quick access to multiple items in a set sequence.

For example, if you work in a healthcare facility and need fast access to patient records, a vertical carousel can do the job beautifully. But remember: vertical carousels have a few quirks, too. Since the trays move as one connected unit, the weight needs to be balanced. Otherwise, things can get a little… wobbly.

Getting to Know Vertical Lift Modules (VLMs)

So, what about vertical lift modules? If vertical carousels are like Ferris wheels, then VLMs are more like those fancy vending machines where you press a button, and—voila!—your snack pops out. VLMs use a clever system where trays are moved by an inserter/extractor. This mechanism brings the specific tray you need directly to a picking bay, so there’s no need to rotate the whole system. It’s fast, precise, and doesn’t require balancing.

One of the coolest things about VLMs? They can handle items of different shapes, sizes, and weights. This makes them super versatile for a variety of storage needs. Have high ceilings? VLMs will make great use of all that vertical space. Plus, their flexibility means they can adapt if your storage needs change over time.

Comparing Vertical Carousels and Vertical Lift Modules

Now that you have a general idea of what each system does, let’s compare them side by side. The goal is to find the best automatic storage retrieval system for your specific warehouse needs. Ready? Let’s go!

1. Space Utilization

Space is valuable in any warehouse, right? Vertical carousels typically max out at about 25 feet in height due to balancing issues. This works fine if your warehouse doesn’t have super high ceilings. On the flip side, VLMs can reach heights of 50 feet or more, making them ideal for maximizing vertical space. If you want to make the most of every inch of your warehouse’s height, VLMs might be the way to go.

2. Weight and Load Distribution

Here’s where things get interesting. Vertical carousels need to distribute weight evenly across all trays to avoid instability. If you’re storing items with similar weights, that’s no problem. But if you mix heavy and light items, balancing can become tricky. VLMs, however, don’t have this issue. You can mix and match heavy and light items without worrying about weight distribution. They’re built to carry heavier objects overall and can be modified as your inventory changes.

3. Flexibility in Tray Size and Configuration

Picture this: you have a mix of small and large items to store. Vertical carousels have fixed trays, so you’re stuck with whatever space you’ve got. This can lead to wasted space if you’re storing items of varying heights. VLMs, however, offer customizable trays. You can store smaller items in one tray and large items in another, with no wasted space. If flexibility and efficient space use are priorities, VLMs are your best bet.

4. Picking Speed and Efficiency

Here’s where the magic of an automatic storage retrieval system really shines! VLMs excel at speed because they bring the specific tray you need directly to the operator. No waiting around for the whole thing to rotate—just quick and accurate picking. This is great for warehouses with lots of orders and time-sensitive operations. Vertical carousels are no slouch, though—they’re great for high-speed batch picking. But for speed and precision on a tray-by-tray basis, VLMs take the lead.

5. Integration with Existing Workflow

No one wants to introduce a system that disrupts everything, right? When choosing an automatic storage retrieval system, you need to think about how it fits into your existing workflow. VLMs offer a “goods-to-person” approach, where items are brought directly to the picker. This reduces walking and searching, which is especially handy if your team handles lots of picking tasks.

Vertical carousels, on the other hand, are great if you need continuous access to items. They’re perfect for tasks that require batch picking or accessing multiple trays in sequence. It all comes down to what kind of work your warehouse does every day.

Other Important Considerations

1. Space Layout and Warehouse Design

Before you install an automatic storage retrieval system, take a look around your warehouse. Do you have high ceilings? A vertical lift module might be perfect. Got more floor space but limited height? A vertical carousel could fit right in. Don’t forget to think about access points, safety zones, and how your system will impact day-to-day traffic flow. Proper planning ensures everything fits together like a puzzle.

2. Software and Technology Integration

A modern automatic storage retrieval system is more than just hardware—it often comes with software to help you manage inventory. Make sure the system you choose integrates smoothly with your existing warehouse management system (WMS). VLMs often come with advanced tracking features, data synchronization, and error reduction tools. Ask your vendor about software compatibility, updates, and technical support.

3. Training and Accessibility

Automated systems can revolutionize your operations, but your team needs to know how to use them. If your new system requires training, make sure you budget time and resources to get everyone up to speed. Vertical lift modules, for example, often have user-friendly interfaces, but training ensures everyone feels confident using the system.

4. Budget and Long-Term ROI

Let’s talk money! Investing in an automatic storage retrieval system can be pricey, but think of it as a long-term investment. VLMs may have a higher upfront cost, but their long-term savings through better space utilization, faster picking, and lower labor costs can be substantial. Vertical carousels are often less expensive upfront but may not offer the same level of efficiency gains over time.

5. Future Scalability

Your business won’t stay the same forever (hopefully). Choose an automatic storage retrieval system that grows with you. VLMs often offer more flexibility to add trays or expand configurations. Vertical carousels, while effective, may be more challenging to modify if your needs change drastically.

Why Choose VLMs for Most Applications?

In most cases, vertical lift modules offer clear advantages over vertical carousels. They’re more space-efficient, flexible, and can handle a variety of storage needs. Plus, their quick “goods-to-person” design cuts down on walking and searching time, making them a favorite for busy warehouses.

That’s not to say vertical carousels don’t have their place. If you need continuous access to records or high-speed batch picking, they can be a great choice. Just make sure you’re aware of their limitations, like weight balancing and fixed tray sizes.

Final Thoughts: Making the Best Choice

Choosing the right automatic storage retrieval system depends on your unique needs. Think about what you’re storing, how your team works, and where your warehouse is headed. Whether you go with a vertical carousel or a vertical lift module, you’re investing in a system that can boost productivity, save space, and keep your team happy.

If you’re ready to transform your warehouse, take a close look at what each system offers. And remember, a great automatic storage retrieval system can feel like a personal assistant for your warehouse—bringing you the right items at the right time and making every day a little smoother.