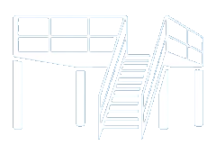

Mezzanine Systems

You can install a warehouse mezzanine system in a new or existing facility to add valuable floor space for manufacturing, material processing or storage. Industrial mezzanine systems are customized for each application and designed to meet specified local codes and OSHA safety requirements. They have both stairways and railings, and are available with various floor surfaces, such as wood, perforated metal and metal grid flooring.

If you’re thinking about expanding your warehouse facility or distribution center, adding industrial mezzanine systems to an existing facility can actually save a great deal of time and money. This is because you do not need to acquire new land or buildings, and existing facility HVAC systems may not require expansion.

Industrial mezzanine systems can be installed inside any facility that has a ceiling height greater than 15 feet. If you have more than 30 feet of overhead space, a multi-level mezzanine can be built to meet your exact area and height requirements.

Advantages of Mezzanine Storage Systems:

- Maximize existing space and double or triple existing square footage without expanding your facility.

- Accommodate lighting, sprinkler pipe, HVAC ducts, electrical and computer conduit.

- Can be designed to meet your exact space requirements and modified to meet future growth needs and planned expansion.

- Improve inventory management and control.

- Can be customized to fit around existing equipment, building columns and other obstructions – even around angled and curved walls.

- Often incorporate wide spans and unique column spacing to free up valuable floor space.

- Available in shelving supported, full mat and freestanding designs.

- Integrates easily with shelving, rack, vertical lifts, carousels, flow rack, in-plant offices, conveyors and much more.

Can be disassembled and moved to another location.

Food-Grade Platforms

From surface finishes to fabrication materials, food grade platforms are generally constructed according to sanitary guidelines that make them “food grade.” Generally, they are to be fabricated and designed in such a way that they can be easily cleaned, inspected, and maintained. When designed properly, food grade mezzanines – used to support both equipment and workers – can reduce, and even eliminate, potential risks of product contamination. By using pre-built structures that simply bolt-in at job sites, platform installation is more efficient and cleaner, allowing production facilities to quickly pass rigid food safety audits and inspections.

Adding a warehouse mezzanine is simpler than what you might think.

In fact, most industrial mezzanines use secure bolt-together connections, and can be dismantled and relocated. What’s more, they qualify for accelerated 7-year capital equipment depreciation, as opposed to the 39 years normally associated with permanent building improvements.

Why Use Outsource Equipment To Meet Your Mezzanine Needs?

We offer end-to-end support for your mezzanine installation project. Our experienced engineers will reduce your time to installation, improve the use of your available space, and seamlessly integrate your mezzanine into your facility.

Outsource Equipment is your premier supplier of warehouse mezzanines and offers various warehouse mezzanine floors and set ups. Whether you need structural I-Beam or roll-formed truss mezzanines, rack-supported or free-standing mezzanines, we have the warehouse mezzanine for you. And if you need help figuring out what industrial mezzanine system or configuration is best for your operation, this form is a good start.